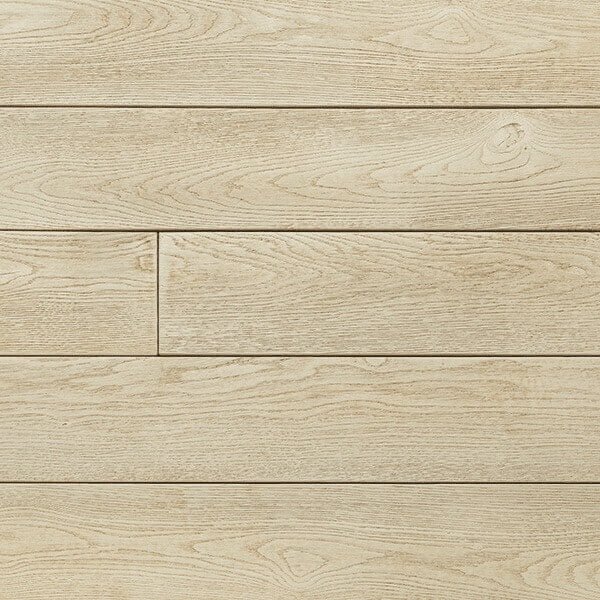

Millboard boards are formed on the basis of carefully selected samples of high-quality oak, reflecting the natural beauty of the original. Only Millboard composite boards are manufactured with this craftsmanship.

The material the board is made of is a new generation RMC (Resin Material Composite), completely free of wood. It consists of a polyurethane resin reinforced with glass fiber with the addition of minerals. Millboard composite boards are solid, colored in mass, do not change volume under the influence of temperature changes, and, unlike wood, they do not absorb water, therefore they do not warp or rot.

Composite boards Millboard

Product lines available

Register your Millboard purchase

As a manufacturer, Millboard requires each installed terrace to be registered on its website. Register your purchase online at www.millboard.co.uk/warranty-registration within 90 days of purchase to activate it and take advantage of the full warranty.

Classic style

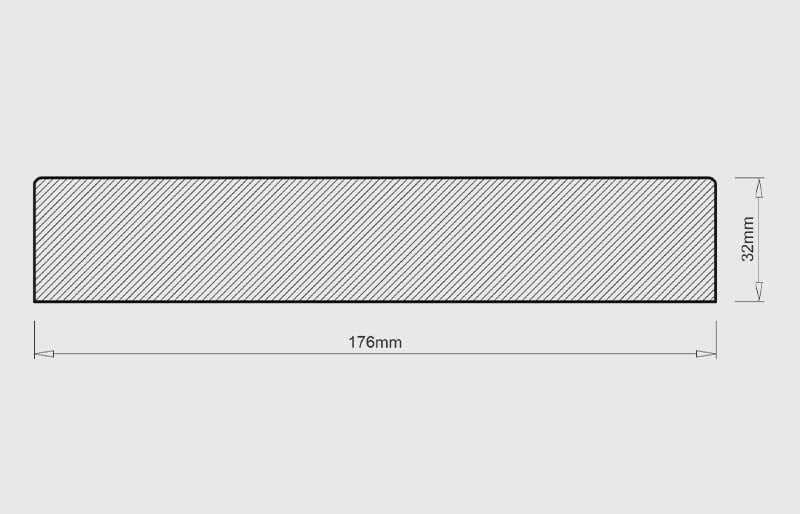

- Model: MDE176

- Waga: 3,16 kg / mb

- Długość: 360 cm

Classic – available colors

Vintage style

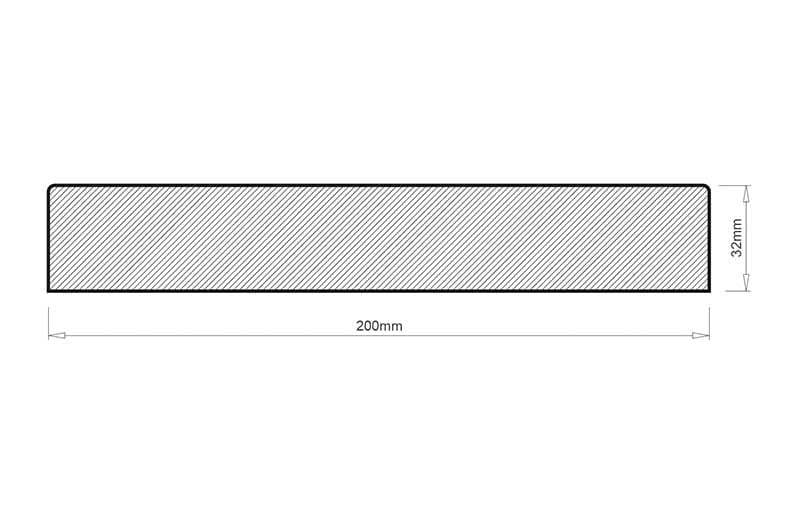

- Model: MDW200

- Waga: 3,47 kg / mb

- Długość: 360 cm

Antiqued – available colors

System items

Millboard – decking systems

Board MDE176

Millboard classic board

Model: MDE176

Weight: 3,16 kg / m

Length: 350 cm

Available colors:

Board MDW200

Millboard vintage board

Model: MDW200

Weight: 3,47 kg / m

Length: 360 cm

Available colors:

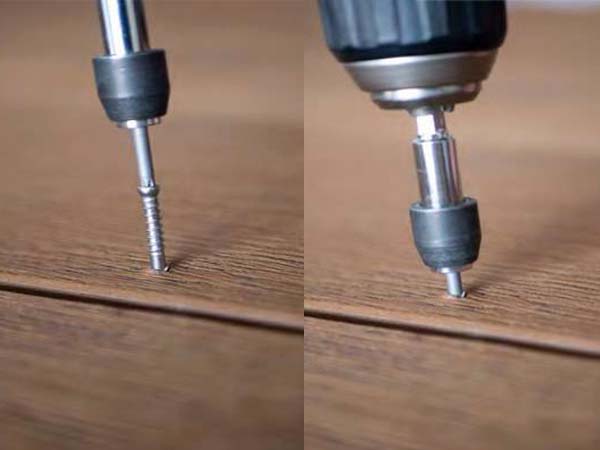

Durafix screws

Durafix Screws Our unique, patented concealed deck fixings make Millboard installation as simple as no other deck. There is no need to drill holes before assembly. The Lastane® material on each Millboard allows the screw to simply sink into the structure of the board, creating an invisible finish. Made of stainless steel, the screws have a six-point Torx head.

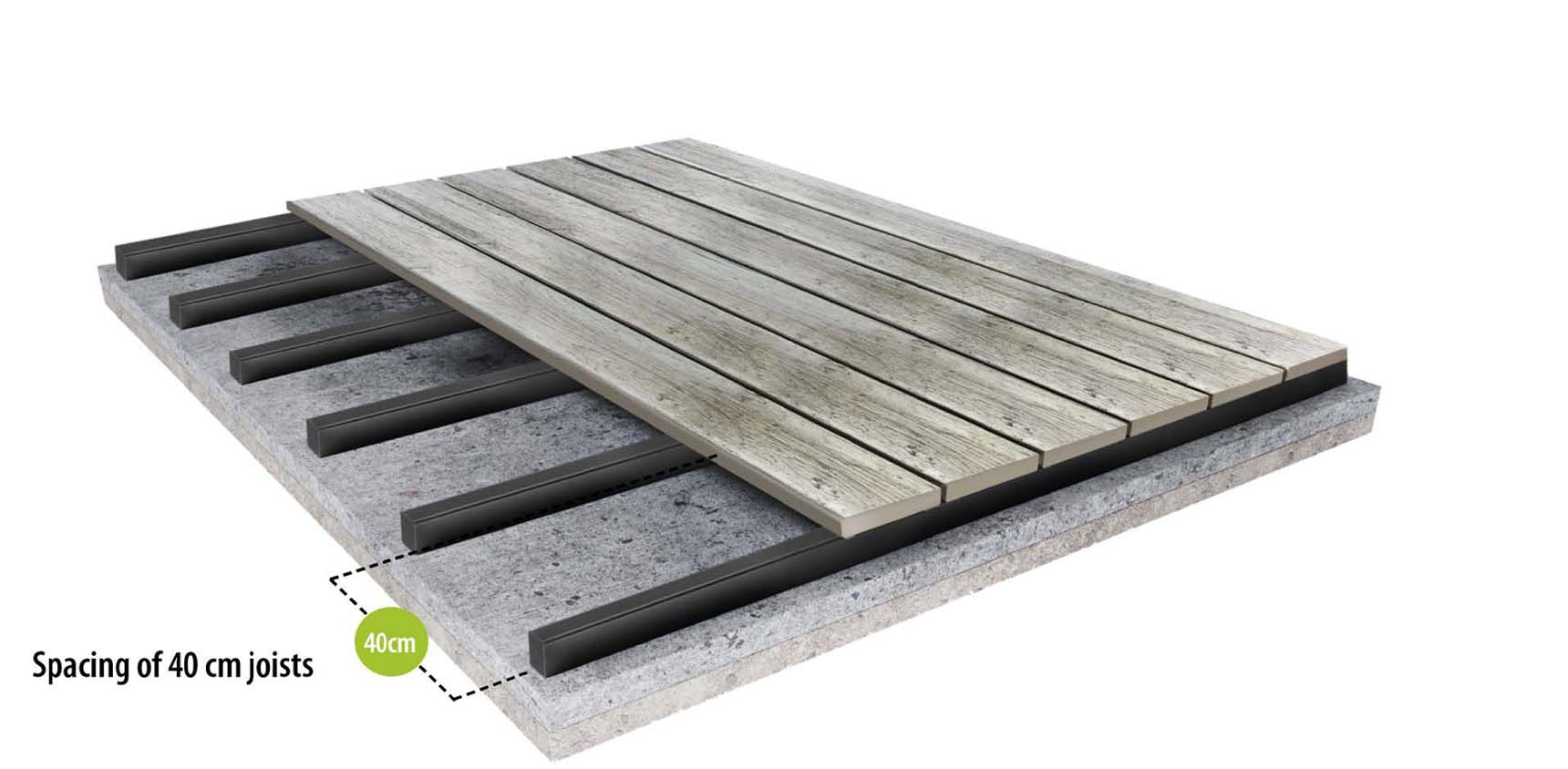

System on concrete

Millboard – decking systems

System on adjustable supports

Millboard – decking systems

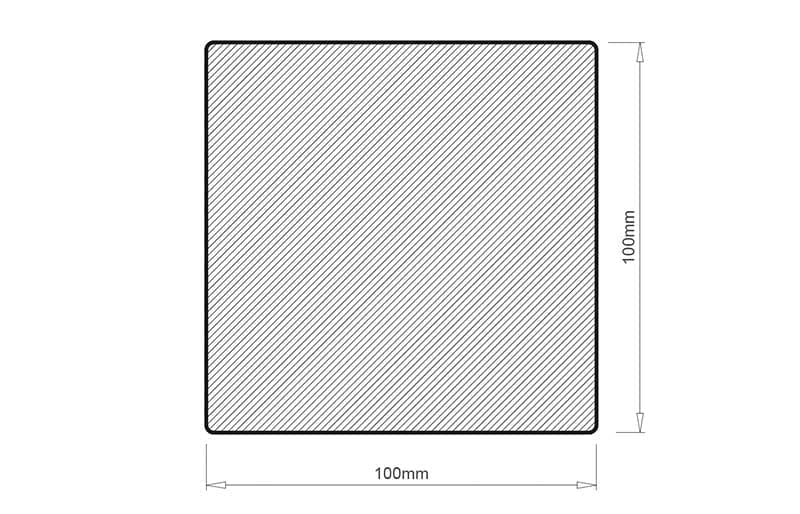

Assembly kit duofix

Our innovative tool ensures quick and easy side fastening. Particularly useful for light colored boards. The guide of the set is placed on the terrace board. You can adjust the board width 145-200 mm. The guide perfectly aligns the screws and also controls the depth of the fastening, ensuring a 6mm gap between the boards.

What should you know about Millboard boards?

Millboard boards are an innovative solution for the construction of terraces or pergolas. The composite from which the Millboard boards are made is based on the pattern of high-quality oak, but does not contain any wood. As a result, the second generation Millboard composite boards are resistant to weather conditions and moisture. In addition, they do not overgrow with vegetation and do not deform as a result of the influence of even the highest and lowest temperatures.

Composite boards offered by Millboard are a combination of polyurethane foam and glass fiber. This mixture guarantees enormous load and mechanical strength. The outer layer of the board is made of the patented Lastane coating with extraordinary flexibility parameters. The coating is responsible for the anti-slip properties of the Millboard decking as well as resistance to dirt and scratches. Durable coloring pigments, resistant to UV radiation, mean that the color of the board does not fade even after many years of exposure to sunlight. What’s more, due to the lack of wood in the composition of the composite and thanks to the Lastane material, Millboard boards do not require any special maintenance, and their cleaning is simple and quick.

Production of Millboard boards

Millboard composite boards are structural parts used to build new generation composite terraces. The material used to create Millboard boards is an ultra-modern RMC (Resin Material Composite). Millboard boards offered by us are colored in the mass, which ensures their unchanged volume regardless of the surrounding conditions.

The highest quality oak samples are used in the production process of the Millboard composite. However, they are not included in the board, but merely serve as a pattern during molding. Thanks to this, the final product resembles a wooden board, while at the same time being devoid of its biggest drawbacks, such as susceptibility to moisture absorption, overgrowing with vegetation or protruding splinters.

Various colors of Millboard

Stylish terraces or patio pergolas are both made in a modern style, with the use of subdued colors, even edges and flat surfaces, as well as structures in the color of dark wood, modeled on classic terraces, which serve all unevenness. That is why, when deciding on the offer from Millboard, composite boards that you can choose are both models with almost smooth and very rough texture. Millboard boards are classified into two product lines – classic and antiqued models.

We know how diverse the expectations of customers are regarding the colors of composite boards. That is why our offer includes as many as 11 different proposals – 8 colors of classic Millboard and 11 colors of antiqued Millboard.

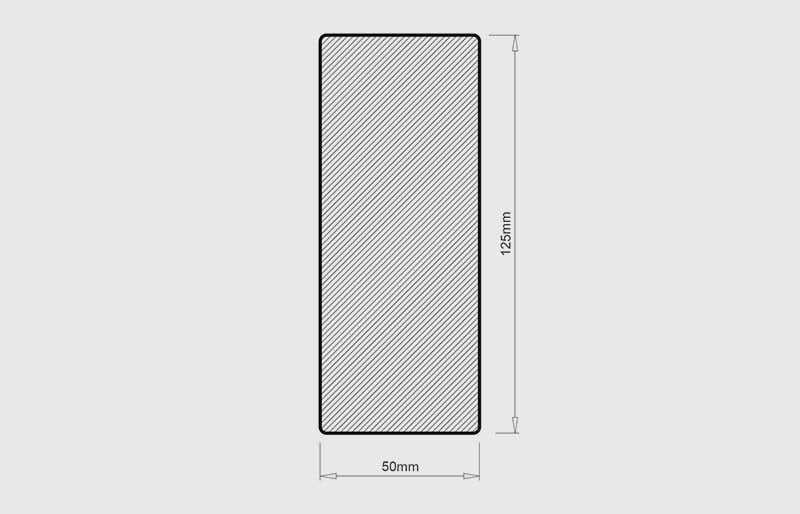

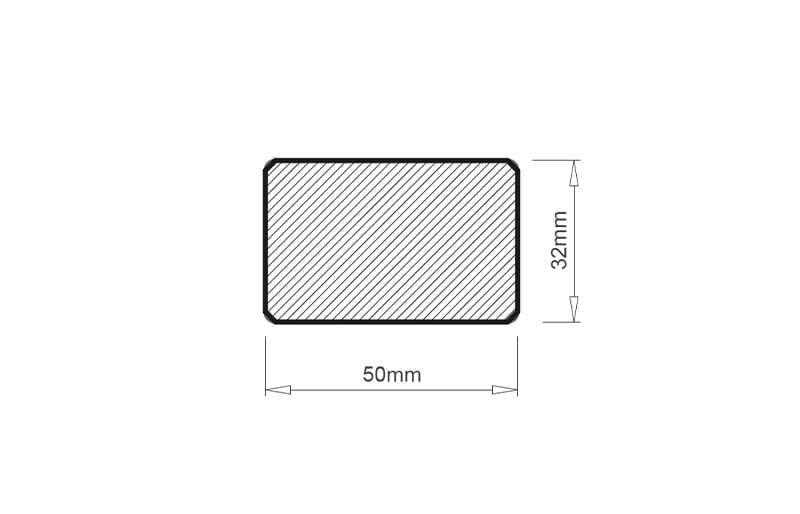

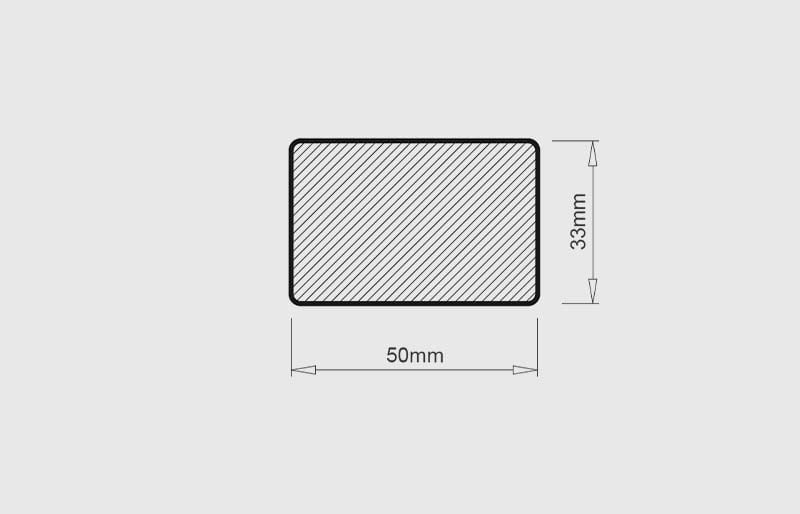

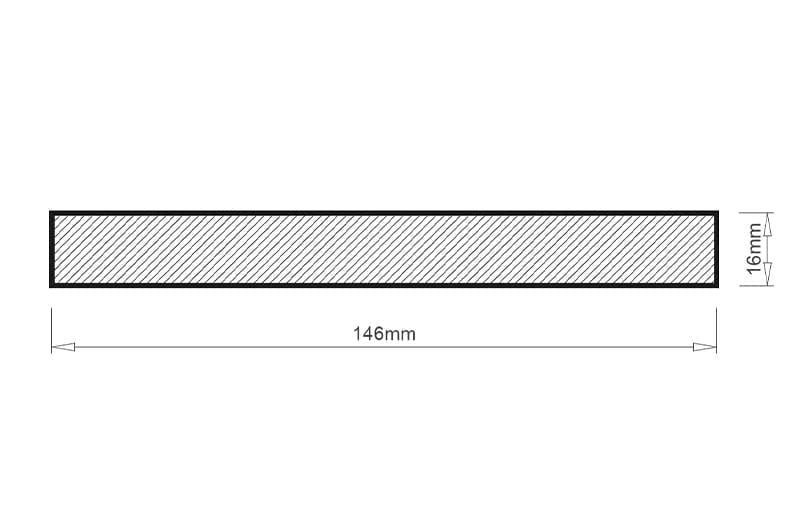

Joists for Millboard boards

The direct base for Millboard boards are joists, without which composite terraces could not exist. The joists used by us for the construction of terraces and wooden (composite) pergolas are a combination of strength and utility. Resistant to deformation and loads, aluminum joists remain light. The use of joists, in conjunction with mounting clips, significantly speeds up the process of building a terrace made of composite boards. When working on structures made of Millboard boards, we use three types of joists, which differ in dimensions and weight.

Millboard Moldings

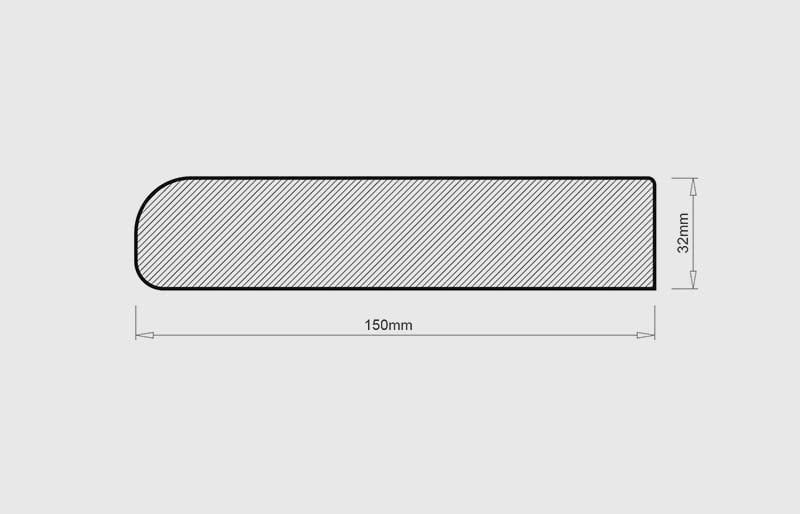

The natural finish of wooden and composite floors are slats. Depending on the dimensions, shapes and use of the structure, we finish terraces and pergolas with selected strips. Our assortment includes standard strips with versatile use, as well as front strips intended for installation in particularly exposed places. In the case of structures with uneven shapes, it is necessary to use a flexible batten, while the use of Millboard boards for the construction of stairs requires lining the stair batten.

Millboard screws

High-quality screws are essential for a structure to be stable, safe and durable. At the same time, in the case of many wooden floors as well as traditional composite floors, the fixing elements disfigure the structure, which is supposed to be aesthetically pleasing. Therefore, when constructing new generation composite terraces, when installing Millboard boards, we use innovative Durafix screws that melt into the surface of the board. Invisible screws do not require drilling, simply sinking into the board, thanks to the innovative Lastane coating.

Durafix screws are made of stainless steel. Thanks to this, they are resistant to moisture and unfavorable weather conditions. They are corrosion-resistant and can withstand even the heaviest loads. They do not deform, guaranteeing a solid assembly of Millboard boards. Each screw has a six-point Torx head.

About us

Lenta® composite boards are a new quality on the market of terrace construction materials. We offer the second generation of the composite – a premium product. Our composite terrace is a structure created with the use of modern materials and breakthrough technologies. As a comprehensive company that meets the expectations of customers, we deal with both the production and sale of composite boards, as well as the implementation of complete projects for the construction of terraces.

Contact us:

Lenta Sp. z o.o.

Grunwaldzka 63

84-230 Rumia

tel. 57 000 24 52

info@lenta.pl

www.lenta.pl